Can be used as a flue gas valve or inlet valve for open, closed. The valve is used in, for example:

| 01 | 02 | 03 | 04 | 05 | |

| Body | SJ355 | SS304 | SS316Ti | SS310 | SS321 |

| Disc | SJ355 | SS304 | SS316Ti | SS310 | SS321 |

| Stem | SS304 | SS304 | SS316Ti | SS310 | SS321 |

| Finish | Coating | / | / | / | / |

| Tmax | 450°C | 600°C | 650°C | 900°C | 1.000°C |

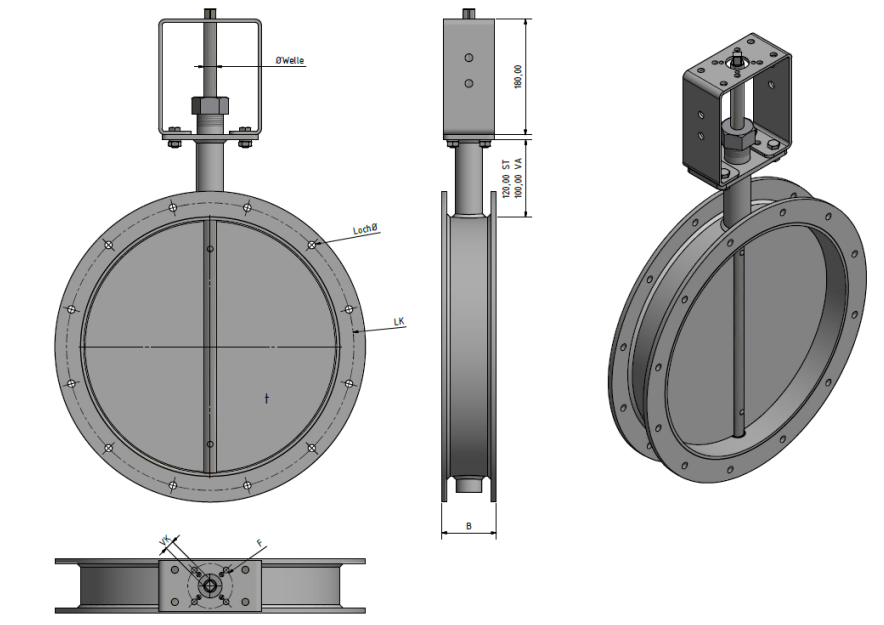

| DN | B | Ø Welle | t | LK | Loch # | Loch Ø | F | VK |

|---|---|---|---|---|---|---|---|---|

| 71 | 70 | 12 | 3 | 110 | 4 | 9,5 | 50/70 | 9 |

| 80 | 70 | 12 | 3 | 118 | 4 | 9,5 | 50/70 | 9 |

| 90 | 70 | 12 | 3 | 128 | 4 | 9,5 | 50/70 | 9 |

| 100 | 70 | 12 | 3 | 139 | 4 | 9,5 | 50/70 | 9 |

| 112 | 70 | 12 | 3 | 151 | 4 | 9,5 | 50/70 | 9 |

| 125 | 70 | 12 | 3 | 165 | 4 | 9,5 | 50/70 | 9 |

| 140 | 70 | 12 | 3 | 182 | 8 | 11,5 | 50/70 | 9 |

| 150 | 70 | 12 | 3 | 191 | 8 | 11,5 | 50/70 | 9 |

| 160 | 70 | 16 | 4 | 200 | 8 | 11,5 | 50/70 | 11 |

| 180 | 70 | 16 | 4 | 219 | 8 | 11,5 | 50/70 | 11 |

| 200 | 70 | 16 | 4 | 241 | 8 | 11,5 | 50/70 | 11 |

| 224 | 70 | 16 | 4 | 265 | 8 | 11,5 | 50/70 | 11 |

| 250 | 70 | 16 | 4 | 292 | 8 | 11,5 | 50/70 | 11 |

| 280 | 85 | 20 | 5 | 332 | 8 | 11,5 | 50/70 | 14 |

| 300 | 85 | 20 | 5 | 349 | 8 | 11,5 | 50/70 | 14 |

| 315 | 85 | 20 | 5 | 366 | 8 | 11,5 | 50/70 | 14 |

| 355 | 85 | 20 | 5 | 405 | 8 | 11,5 | 50/70 | 14 |

| 400 | 85 | 20 | 5 | 448 | 12 | 11,5 | 50/70 | 14 |

| 450 | 85 | 20 | 5 | 497 | 12 | 11,5 | 50/70 | 14 |

| 500 | 85 | 20 | 5 | 551 | 12 | 11,5 | 50/70 | 14 |

| 560 | 100 | 25 | 6 | 629 | 16 | 14 | 70/102 | 17 |

| 600 | 100 | 25 | 6 | 665 | 16 | 14 | 70/102 | 17 |

| 630 | 100 | 25 | 6 | 698 | 16 | 14 | 70/102 | 17 |

| 710 | 100 | 25 | 6 | 775 | 16 | 14 | 70/102 | 17 |

| 800 | 100 | 30 | 6 | 861 | 24 | 14 | 70/102 | 22 |

| 900 | 100 | 30 | 6 | 958 | 24 | 14 | 70/102 | 22 |

| 1000 | 100 | 30 | 6 | 1067 | 24 | 14 | 70/102 | 22 |

| 1120 | 140 | 40 | 8 | 1200 | 32 | 18 | 70/102 | 27 |

| 1250 | 140 | 40 | 8 | 1337 | 32 | 18 | 70/102 | 27 |

| 1400 | 140 | 40 | 8 | 1475 | 32 | 18 | 70/102 | 27 |

| 1600 | 200 | 40 | 10 | 1675 | 40 | 18 | 125/140 | 27 |

| 1800 | 200 | 40 | 10 | 1875 | 40 | 18 | 125/140 | 27 |

| 2000 | 200 | 40 | 10 | 2073 | 40 | 18 | 125/140 | 27 |

* mm

** Dimensions may vary due to temperature and pressure